Condition-Based Monitoring for a Construction Aggregate Plant’s Industrial Systems

12-09-2019

The Challenge

A construction aggregate plant operates 10 high horsepower, secondary crusher drive motors and associated conveyor belts, producing 600 tons of product per hour. All heavy equipment requires maintenance, but the aggregate producer’s costs were greatly magnified anytime necessary maintenance was unplanned and unscheduled. The product must be supplied to the customers on a tight schedule to fulfill contracts, avoid penalties and prevent loss of future business. Furthermore, a sudden failure in one of the drive motors would cause rock to pile up in unwanted locations, extending downtime and increasing costs.

Clearly, preventative maintenance was preferable to unexpected failures. So, twice each year, the company brought in an outside vendor to attach sensors to the motors to do vibration studies, measure bearing temperatures and attempt to assess the health of the motors. But that was not enough. Unexpected breakdowns continued to occur. The aggregate producer decided to upgrade to a Condition-Based Monitoring (CBM) sensor system that could continually monitor the motors in real time, apply data analytics to detect changes in motor behavior before they developed into major problems, and alert maintenance staff – via email or text – anywhere they happened to be.

A wired sensor network would have been cost prohibitive. An aggregate plant has numerous heavy vehicles moving around, so any cabling would have to be protected. Additionally, the plant covers 400 acres and the cable would have to be trenched to numerous locations. Cable simply was not an option. The aggregate producer needed a wireless solution.

The Solution

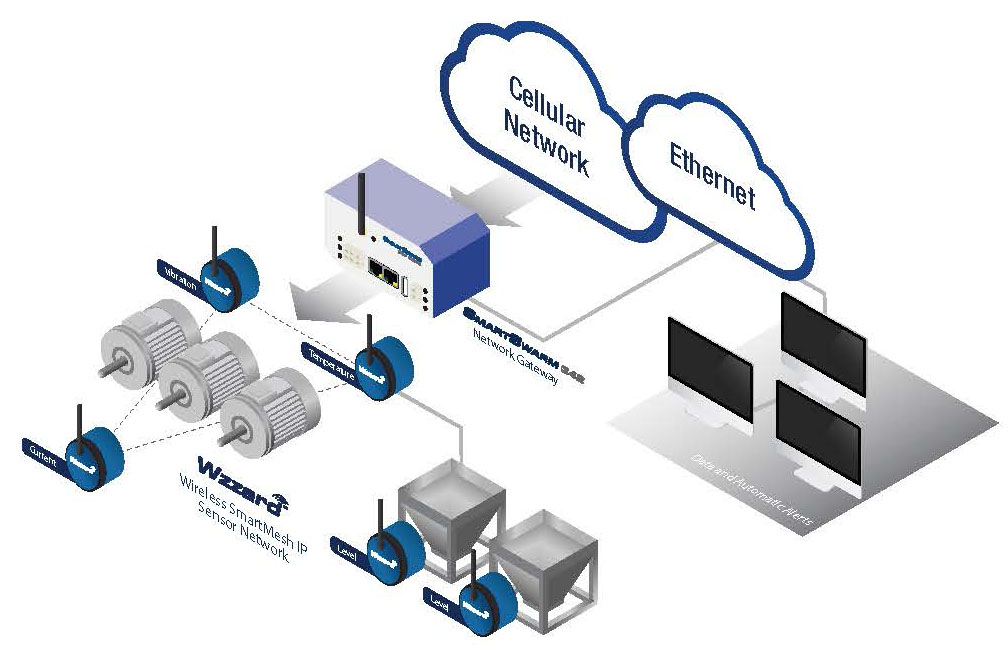

Advantech installed the Wzzard Mesh Wireless Sensor Platform. First, each motor was equipped with three industry standard sensors: current draw, vibration and temperature. Changes in any of these parameters can be an early indicator of future problems. Each motor was provided with a single Wzzard mesh wireless sensor edge node, with each node capable of connecting up to three sensors. The Wzzard edge nodes then used wireless mesh networking to publish the sensor data to a network gateway. The gateway then sent the data to the monitoring application.

Two additional Wzzard nodes were also installed to provide data routing support and to ensure the mesh network was robust enough to provide reliable, five nines (99.999 percent) uptime and connectivity, even though the environment included many large metal surfaces.

Why Wireless?

When sensors are spread out across a wide area, establishing a wired sensor network may be impractical. At a quarry site, for example, there is a lot of heavy equipment moving around so, above ground cabling would be in constant danger. Trenching the cable would protect it, but trenching costs $15 USD/foot or more for cabling, conduit and installation. The quarry’s farthest motor is 840 feet from the control center; wiring that single motor would cost $12,600 with nine more motors to go.

A wireless Wzzard mesh network installation is not only less expensive than running cable to all of the monitoring points in the quarry, it cannot be severed by mobile equipment or digging.

Wzzard Intelligent Sensing Platform

- Wzzard mesh wireless networks cover distances where a network of wired sensors would be cost prohibitive.

- The Wzzard mesh wireless network is an easy retrofit – it works with existing, industry-standard sensors.

- The monitored machines need no data ports – Wzzard edge nodes collect relevant information from external sensors.

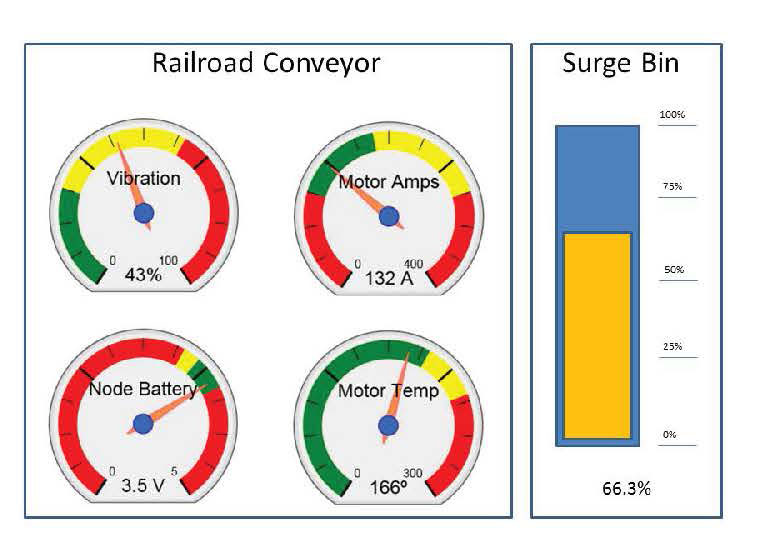

- Real-time access to data through an intuitive dashboard.

- Data analytics not only detects failures, it predicts failures.

- Alert levels set to provide real-time text message or email notification of thresholds exceeded.

- Wzzard cuts downtime and related costs.

- Wzzard makes machine condition data available wherever it is useful.

- Wzzard enables automatic alerts on your computer, tablet or smart phone.

Connect Anything, Monitor Everything

Since Wzzard Mesh Wireless Sensor Nodes can connect

virtually any sensor, the aggregate producer also decided to install

level meters in the surge bins. Like the sensors on the motors, these

sensors were connected to Wzzard mesh wireless sensor nodes, which

joined the other intelligent nodes on the mesh network. If the surge

bins were in danger of overflowing, the system would send immediate

alerts to the operator.

- Motor Vibration

- Motor Current Draw

- Motor Temperature

- Node Battery Status

- Surge Bin Level

ADDITIONAL CBM QUARRY APPLICATIONS

- Rock breaker

- Apron feeder to the primary crusher

- Overhead crane Dust collection/suppression system

- Freight elevator Eccentric trolley removal cart

- Service air compressor

- Man-lift elevator

- Sump pumps

- Air cannons

- Air vacuum clean up systems

- Water booster pumps

- Rock grapple

- Service trolleys

- Conveyor belt magnets

- Conveyor gravity take-up service winch

- Conveyor belt metal detectors

- Conveyor belt rip detector

- Belt monitoring systems

- Conveyor belt weigh scales

- Belt feeders

- Vibratory feeders

- Screw feeders

- Lime/cement silos

- Bin ventilators

- Sampling stations