Location: Singapore

Project Introduction

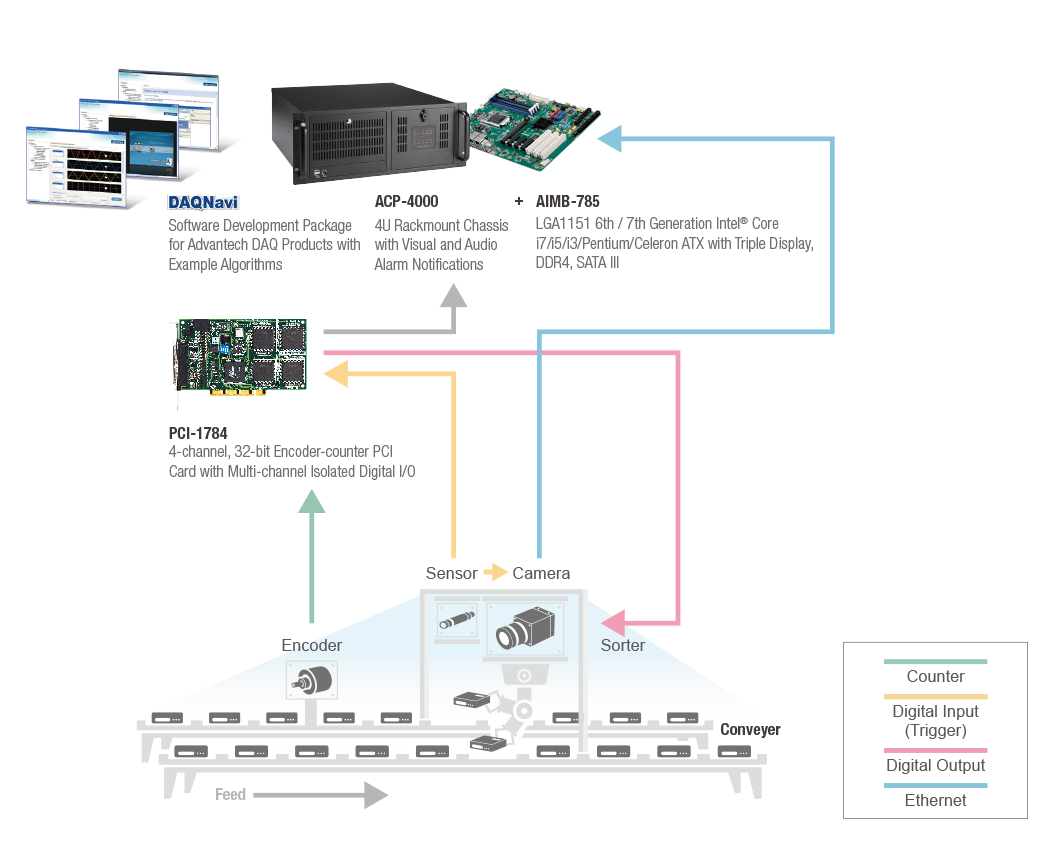

Using data acquisition and computing to track workpiece locations on conveyer belts is extremely important for the successful introduction of automated inspection and sorting systems. To complete the automation process, systems developers need highly stable control units and signal acquisition cards, as well as readily available software for necessary algorithms. To meet this need, Advantech offers a turn-key solution featuring industrial computers, encoder-counter PCI acquisition cards, and demonstrative algorithm programs. Advantech’s technical support team solves systems development problems to enable the rapid implementation of automated inspection and sorting processes in the factory production line.

System Requirements

The company deployed the first automated inspection and sorting system at its Singapore plant. The new system automatically records inspection data and conducts sorting operations according to the inspection results. Non-defective, degraded, and defective products were routed to different workstations for subsequent handling. To complete the automated processing, the production line integrated with an industrial computer equipped with a signal acquisition card. The card was used to receive signals from encoders and sensors on the conveyer belt, store images, and transmit trigger signals to the sorter. Although the company is capable of developing hardware and software solutions, the process of automating operations is quite complex. Therefore, the company required a supplier that would be capable of providing the relevant software and technical support to address multiple function and sequencing issues.

System Description

The entire inspection process can be divided into the following four steps: 1) As workpieces are placed on the conveyer belt for inspection, the control unit reads the encoder signal to obtain location data. 2) When the workpiece reaches the location sensor, the sensor transmits a signal to the inspection unit and the PCI-1784U card. 3) The camera (or other inspection unit) receiving the signal then begins inspection operations, transmitting the results to the control unit. 4) As the workpiece continues moving along the conveyor belt, the control unit processes the location data and transmits trigger signals to the sorter. The sorter then sorts the workpieces within the specified unit range, thereby completing automated inspection and sorting. Equipped with a 6th generation Intel® Core™ i7/i5/i3/Pentium®/Celeron® processor, AIMB-785 is a high-performance, industrial-grade embedded ATX motherboard ideal for large-volume data acquisition and computing. Accordingly, although quality inspections involve many workpieces moving rapidly on the production conveyer belt, Advantech’s AIMB-785 system has the performance capabilities to handle such applications. [PW1]PLEASE CHECK What industrial computer? This has not been introduced. I assume you are referring to the solution provided by Advantech. But please double check the sentence to ensure accuracy.

Project Implementation

- ACP-4000: 4U Rackmount Chassiswith Visual and Audio AlarmNotifications

- AIMB-785: LGA1151 6th / 7th Generation Intel®Core™ i7/i5/i3/Pentium/Celeron ATXwith Triple Display, DDR4, SATA III

- PCI-1784U: 4-channel, 32-bit EncodercounterPCI Card with MultichannelIsolated Digital I/O

- DAQNavi: Software Development Packagefor Advantech DAQ Productswith Example Algorithms

System Diagram

Conclusion

The essential functions of automated inspection and sorting systems include encoder signal receiving, locating, and unit triggering.For this project, Advantech offered a comprehensive integrated software-hardware solution that satisfied the manufacturer’s usage requirements. Accordingly, the manufacturer did not incur high initial investment costs for unnecessary functions, nor have to worry that inadequate functions would render the system ineffective. Moreover,with Advantech’s technical support, the company was able to cost effectively develop an appropriate application system.

Advantech’s PCI-1784U card and custom algorithms provide practical functionality and widespread applicability for diverse manufacturing facilities. System developers with similar requirements can easily modify the parameters to employ the same example algorithms. Advantech offers integrated solutions that allow companies to maximize production efficiency by automating the inspection and sorting process.

/Rackmount chassis IPC-611_G.gif)

/ACP-4340_Front Left _S20170825181047.jpg)

/DAQ Navi_S20130822162332.png)

/ACP-4010_front_right_G20100826114716.gif)

/IPC-631_Front right 20161227160212.jpg)